Machine Manufacturing

discover our product

Scroll down

Scroll down

Scroll down

Scroll down

Scroll down

Scroll down

Scroll down

2025

How Does It Work?

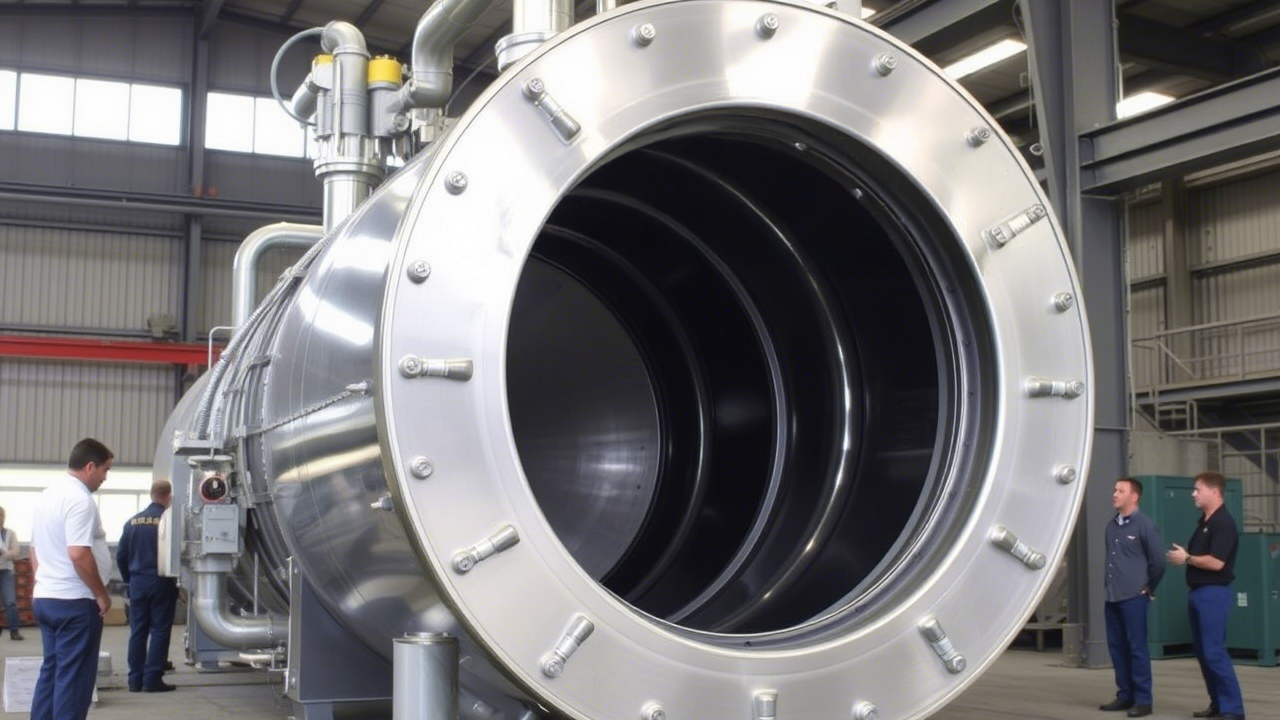

Durable Construction Based on High-Quality Materials

Our pyrolysis machines for used tires are designed with durability, safety, and operational efficiency in mind. Each component is made from selected materials resistant to extreme temperatures and aggressive chemical environments.

In particular, we use:

Heat and acid-resistant steels – in pyrolysis reactors and process pipelines, resistant to corrosion and high temperatures.

High-grade industrial seals – preventing gas emissions and increasing system tightness.

Thermal and fireproof insulation – minimizing energy loss and protecting the surrounding environment.

Information Required from the Client

The machine manufacturing process consists of several key elements.

To properly select a machine to suit your needs, the following information is required:

Type of tires being processed – passenger, truck, industrial, or agricultural (each has different material and performance requirements).

Planned production capacity – in tons per day or month.

Automation preferences – manual loading, semi-automatic, or fully automated lines.

Available facility space – for the reactor, purification units, and storage of raw materials and products.

Environmental regulations – related to local emission, waste, and industrial installation requirements.

Desired end products – whether the investor plans to further process oil, carbon black, steel, or pyrolysis gas.

Intended financing model – purchase, leasing, or technology partnership.

Our Facilities and Capabilities

Wide Range of Cooperation

Why choose our solutions:

Full project and execution – from documentation to commissioning

Scalable plant capacities – from compact to industrial scale

Professional service and after-sales support

Environmental advisory and assistance in obtaining administrative decisions

Technology compliant with closed-loop economy principles (CLE)

Safety as a Priority at Every Stage

Safety features include both passive and active systems.

Each installation is equipped with:

Temperature, pressure, and gas level sensors – integrated with automatic shutdown in case of malfunction.

Emission control and neutralization systems – filtration of pyrolysis gases and protection against leakage of hazardous substances.

Emergency cooling and ventilation systems – in case of exceeding process parameters.

Remote monitoring – ability to supervise and control the process via app or operator panel.